1. Yield Limit Theory (Automated)

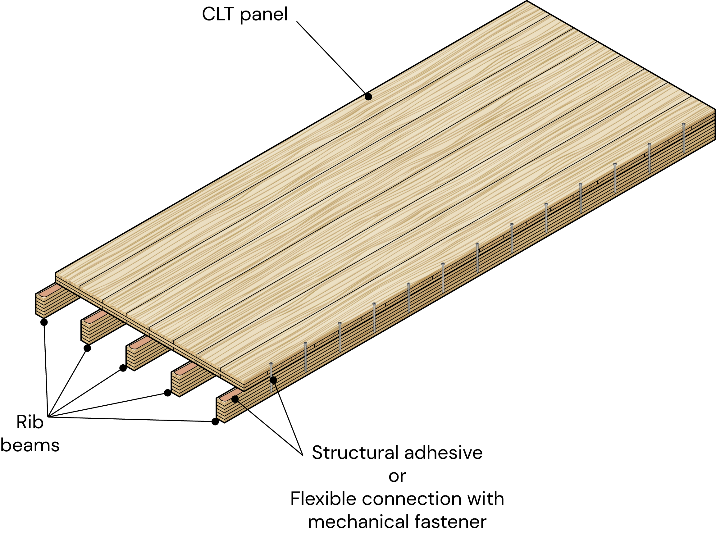

CSA O86 requires checking multiple yield modes to find the “Unit Lateral Strength” ($n_u$).

Our calculator runs the full matrix:

- Mode a, b: Wood embedment failure (Main or Side member).

- Mode d: Fastener yielding with wood crushing.

- Mode e, f, g: Double curvature yielding (Plastic hinge formation).

- Feature: The tool identifies the governing mode. If it’s a ductile mode (steel yield), it allows for a more efficient design than brittle wood failure.

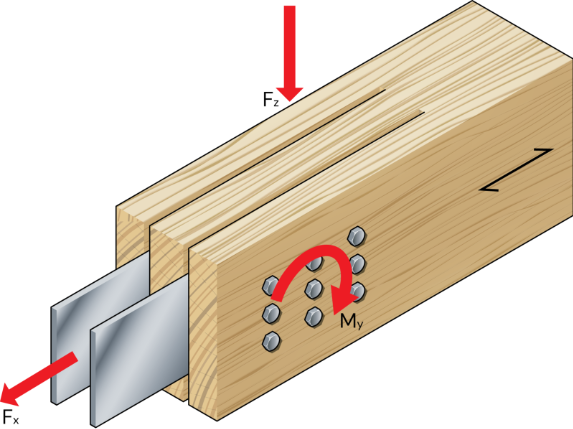

2. Combined Actions (Moment + Shear)

Standard CSA tables don’t tell you how to handle a moment-resisting knee connection.

Our module uses a Rational Analysis (Elastic Method). It resolves the applied Moment, Shear, and Axial forces into a resultant vector for every bolt. It then checks this resultant against the bolt’s capacity at that specific angle to grain ($N_{r,\theta}$), ensuring the “corner bolts” don’t fail.

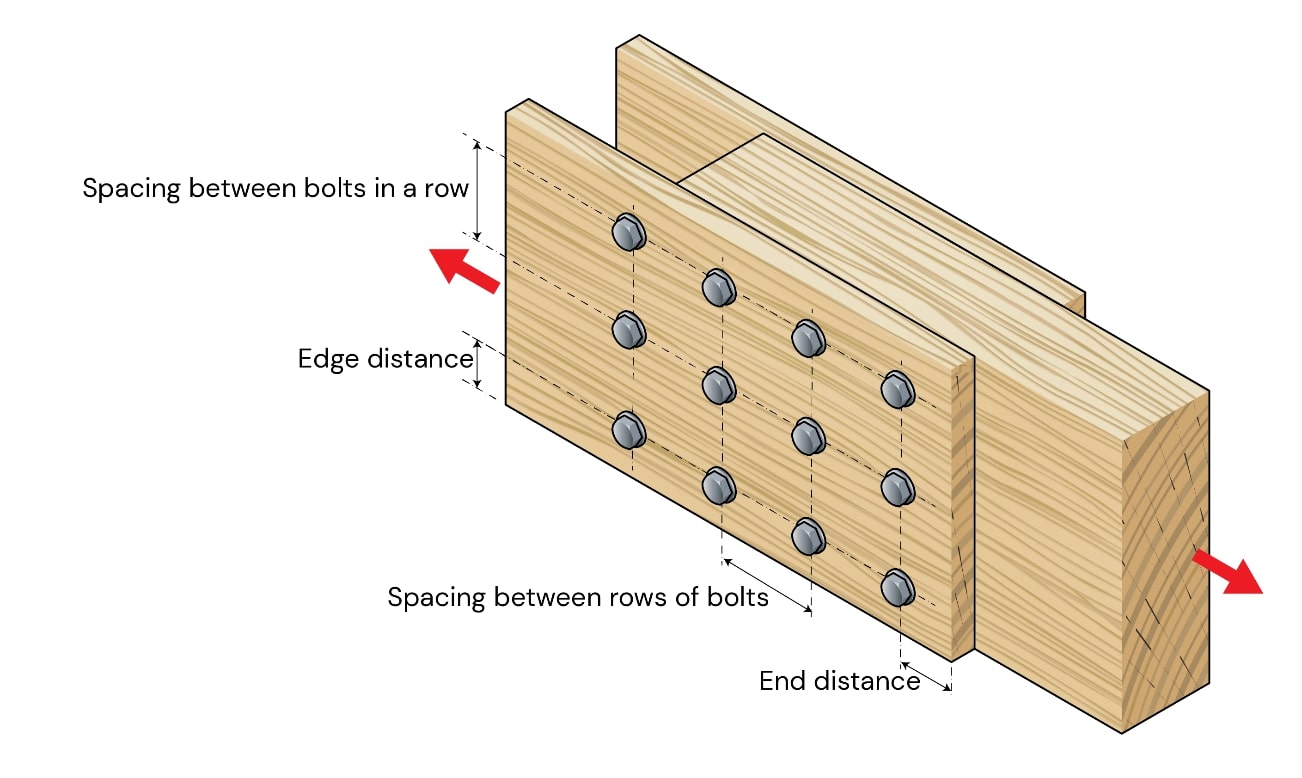

3. The Group Effect ($J_G$)

In a long row of bolts, the load is not shared equally.

The calculator calculates the Group Effect Factor ($J_G$) based on the number of fasteners per row, the stiffness of the members, and the ductility of the connection. This prevents the dangerous overestimation of capacity in large tension splices.