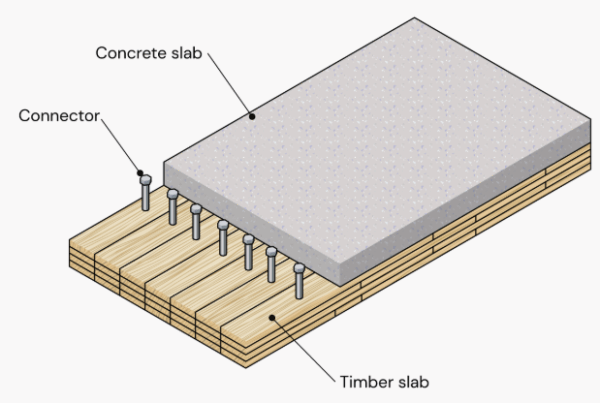

As mass timber construction continues to gain prominence in the building industry, driven by its sustainability credentials and structural capabilities, the demand for more elaborate and high-strength connections has increased. Engineers are pushing the boundaries of design, specifying intricate joinery and robust fastening systems to harness the full potential of this innovative material. However, amidst this rapid evolution, a critical consideration often gets overlooked: hydrogen embrittlement (HE). This phenomenon can compromise the screws and fasteners that hold these massive timber structures together, threatening to undermine their integrity and longevity. As the stakes grow higher, it is imperative for engineers to prioritise HE mitigation strategies, ensuring that the connections underpinning mass timber’s future remain strong, reliable, and safe.

Hydrogen embrittlement, also known as hydrogen cracking, causes fasteners to break suddenly, usually during a short period after assembly (hours to weeks). The material irregularities that lead to hydrogen embrittlement are almost impossible to spot after manufacturing. As a result, products are often shipped and assembled before the problem is discovered. This can lead to costly recalls and, in the worst-case scenario, partial collapse of a structure. Hydrogen embrittlement, a silent killer, can strike at any time.

Hydrogen embrittlement is classified under two categories based on the source of hydrogen:

– Internal Hydrogen Embrittlement (IHE)

– Environmental Hydrogen Embrittlement (EHE).

IHE is caused by residual hydrogen from steelmaking or from processing steps such as pickling and electroplating. EHE is caused by hydrogen introduced into the metal from external sources while it is under stress

Hydrogen embrittlement susceptibility is a function of the material condition, which is described by the metallurgical and mechanical properties of a material such as steel. This is the fundamental basis for understanding HE phenomena, which is the study of how a stressed material performs in the absence and then in the presence of absorbed hydrogen.

Even more simply put, the material state of the steel is a root cause, while tensile stress and absorption of hydrogen from the environment are triggers for hydrogen embrittlement.

Internal hydrogen embrittlement

Internal hydrogen embrittlement is caused by residual hydrogen from steelmaking or due to absorbing hydrogen during processing steps such as pickling and electroplating.

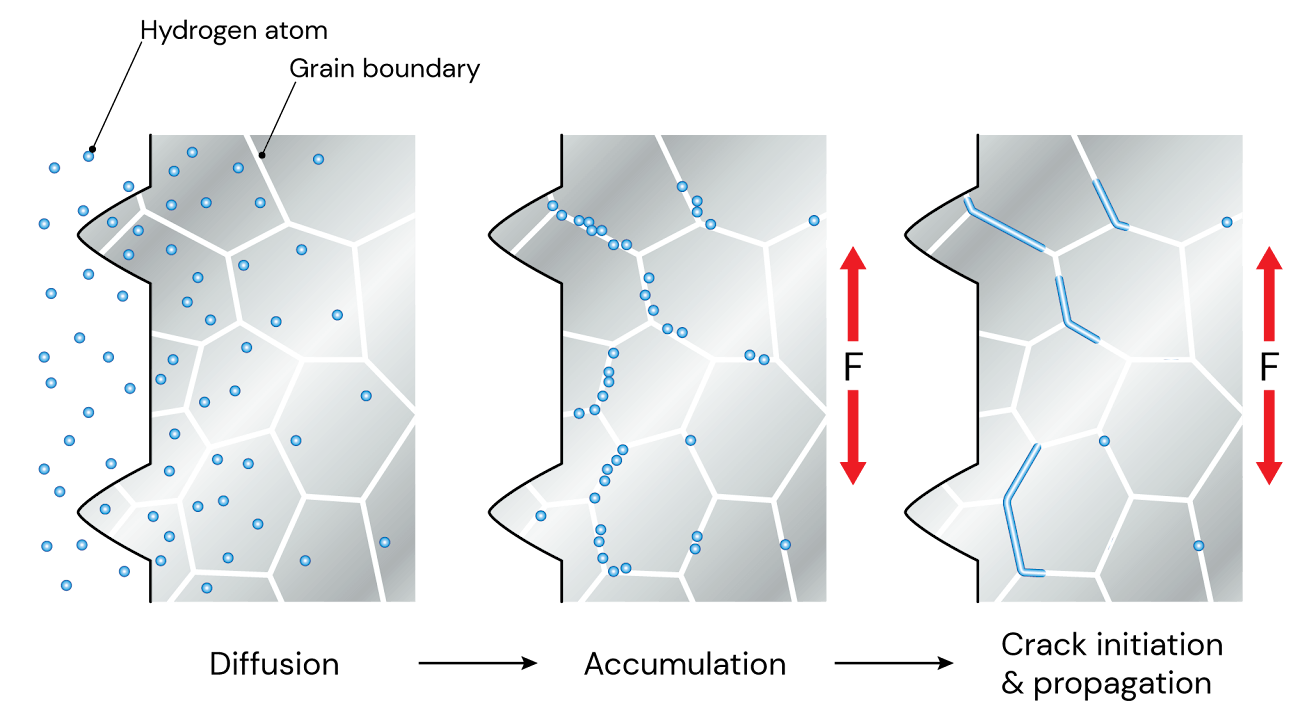

During manufacturing, certain processing steps expose fasteners to environments conducive to hydrogen absorption. This causes hydrogen atoms to form on the surface of the fastener and diffuse into the steel.

The most influential processes for hydrogen absorption are pickling, followed by electrolytic zinc plating, while heat treatment plays a relatively minor role in the context of timber screws.

Pickling is a crucial step in screw production that removes surface oxides, rust, and scale to prepare the metal for subsequent processes like coating or heat treatment. The process typically involves soaking screws in an acidic solution, often after initial cleaning, followed by rinsing to remove corrosive residues.

Acidic solutions used in pickling generate hydrogen as a by-product, which is absorbed into the steel. This process is the main contributor to hydrogen absorption during manufacturing. This is especially relevant for high-strength screws, because their microstructure retains hydrogen more effectively.

During electrolytic zinc plating, hydrogen is generated on the screw’s surface and can diffuse into the material.

Internal hydrogen embrittlement failure usually happens hours to days after installation and is the fault of the supplier for the lack of production quality control. Fastener hardness should be limited, and production processes with low hydrogen absorption should be implemented.

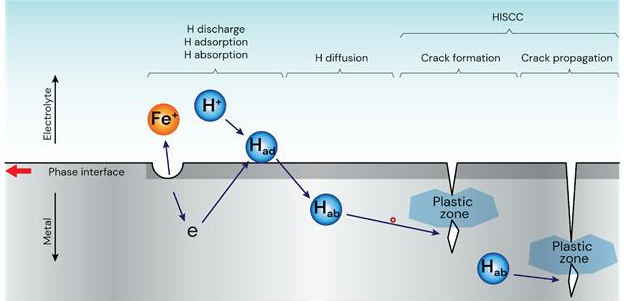

Environmental hydrogen embrittlement

Environmental hydrogen embrittlement is caused by diffusion of hydrogen into the screw from the environment, and in the presence of discontinuation of the screw coating, it will cause crack formation and crack propagation in the screw. The hydrogen that is absorbed is the by-product of screw surface corrosion, occurring through electrochemical reactions in the presence of water, particularly in acidic or chloride-rich conditions.

Discontinuation of the coating can be caused by surface corrosion due to prolonged exposure to moisture. This will lead to hydrogen embrittlement failure after a longer period. Damage to the coating can also be caused on-site due to over-torque or improper installation angle. This will lead to a quicker hydrogen embrittlement failure.

Environmental hydrogen embrittlement failure usually happens days to weeks after installation.

Reducing the risk of environmental hydrogen embrittlement

Reducing the risk of internal hydrogen embrittlement is the responsibility of the screw manufacturer, and many manufacturers already have certain protocols in place to reduce the probability of IHE as much as possible.

Rothoblaas incorporates the use of inhibitors in pickling baths to suppress hydrogen generation and post-zinc plating treatments for dehydrogenation at 150–200°C for longer screws. Eurotec uses a two-stage tempering process, before galvanising and after hardening of the screws, in order to reduce internal stresses in the metal and modify the microstructure to minimise hydrogen diffusion. Schmid’s screws were subject to a study performed by the Institute of Timber Engineering and Wood Technology, as well as the Institute of Material Science, Joining, and Forming (IMAT) of the Graz University of Technology. The study measured the content of hydrogen in screws during and after manufacturing, and the study has concluded that Schmid RAPID® screws are stored under controlled conditions that prevent internal hydrogen embrittlement (IHE). Proper storage ensures that any hydrogen introduced during manufacturing naturally diffuses out, eliminating the risk of IHE in the finished screws.

Prevention of environmental hydrogen embrittlement is a shared responsibility between the screw manufacturer, designer and on-site installer.

The responsibility of the manufacturer is to reduce material susceptibility to hydrogen embrittlement. The key product characteristics that must be controlled are:

- Core hardness

- Surface hardness

- Case depth.

The responsibility of the designer is to limit moisture exposure of wood in the project, limit the use of steel to timber connections with thick steel plates (swelling of timber in connections with thick steel plates causes prolonged tension in the screws) and to spec out correct screws for the intended environment (for projects with higher moisture content screws with a higher corrosion class and lower core hardness should be used).

The responsibility of the construction crew is to limit the exposure to moisture of the timber elements during construction and to correctly install the screws without over-torqueing.

In order to prevent faulty manufacturing, which will result in internal hydrogen embrittlement, certain design codes and test measures have been put in place in the past decades.

- ISO 15330 presents preloading tests used for the detection of hydrogen embrittlement.

- ASTM F1941 is a standard for electrodeposited coatings on threaded fasteners in North America and provides mandatory steps to prevent internal hydrogen embrittlement.

- ASTM F1624 provides the standard test method for measurement of hydrogen embrittlement threshold in steel by the incremental step loading technique.

- ASME B18.6.3, Section 4.11.5 provides tests for hydrogen embrittlement, which are more applicable for case-hardened fasteners

Currently, the only design code that has provisions to reduce the risk of environmental hydrogen embrittlement in screws used in timber structures is the CSA 084:2024, which has the following provisions.

- All fasteners for timber applications shall conform to CSA O86:24 as a minimum.

- All case-hardened, carbon-steel, self-tapping wood screws must have a core hardness ≤ 390 HV, in accordance with ISO 2702. For case-hardened, carbon-steel fasteners used in wet service conditions, the core hardness must be ≤ 360 HV. Wet service condition application will require additional measures to prevent corrosion.

- All case-hardened, carbon-steel, self-tapping wood screws with core hardness between 360 HV and 390 HV must have an additional quality assurance plan in accordance with ASTM F606 Clause 7 or ISO 15330.

- Electroplated fasteners must be manufactured per ISO 4042 or ASTM F1941, with a zinc coating thickness of at least 8 μm.

- Follow the manufacturer’s installation instructions, including recommended tools, drive-in torque limits, and pre-drilling requirements.

- For dry service conditions, the timber moisture content (MC) should average 15% or lower throughout the year and must not exceed 19% at any time.

- Fasteners before installation must be stored in a dry environment to prevent exposure to moisture and other corrosive elements.

- All fasteners must be approved by the Structural Engineer of Record (EOR) before installation.

Resources

Case-Hardened Steel Fasteners & Mass Timber Construction: Eric McDonnell, Bjørn Stankowitz and Felix Scheibmair

https://cms.timberunlimited.co.nz/assets/Resources/Case-Hardened-Steel-Fasteners_Tech-Note_FINAL.pdf?v=1733865936

Fundamentals of Hydrogen Embrittlement in Steel Fasteners: Salim Brahimi, IBECA Corp.

https://www.boltcouncil.org/files/HydrogenEmbrittlementInSteelFasteners-Brahimi.pdf

https://www.rothoblaas.com/blog/hydrogen-embrittlement-and-other-risk-factors

https://www.eurotec.team/en/know-how/technical-articles/hydrogen-embrittlement-civil-engineering

https://www.schmid-screw.com/news-blog/hydrogen-embrittlement-research-project-screw-hiscc